You must be surprised to see the title talking about floor tiles or vitrified tiles right? You must be thinking “What this tiles related topic is doing here on tech blog?” Let me tell you why!

Recently we visited one factory manufacturing floor tiles and I was surprised to see the way they are using technology. In this article, we are going to show you the way floor tiles or vitrified tiles industry is getting changed with the help of digital floor tiles design technology. This not only helps them to increase the production but also helps them to maintain the uniform design through the manufacturing process.

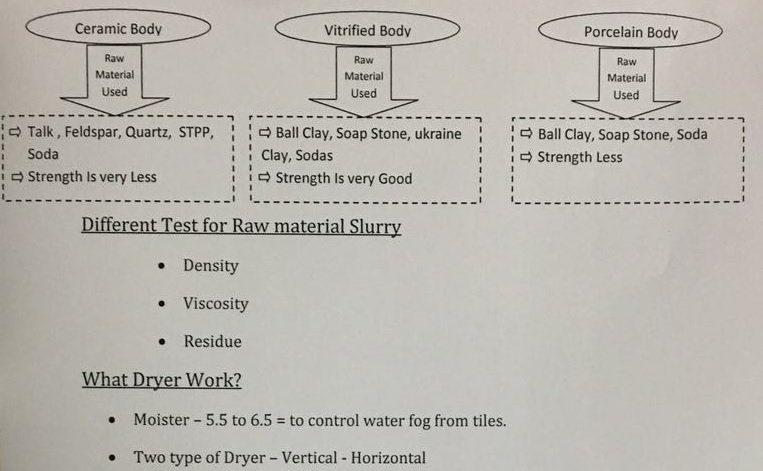

Building a home or a work space is something that you might do with lots of dreams. Looking for the minute details is what many do for sure, to ensure the structure gets the best stuff in all areas. Here is a brief description of the tiles that comes handy, whenever you want to fix tiles while the construction of new structures goes on, or when remodeling is happening. The vitrified tile is a ceramic tile with very poor porosity. It is an options to marble and granite flooring.

Here is the detailed diagram depict the manufacturing process of digital floor tiles:

Digital floor tiles manufacturing benefits:

- Improves the manufacturing process

- Improves the design precision

- Increase production speed

- Can create complex designs on the tiles

Apart from these, it also offers various benefits to the manufacturer. The only drawback of this technology is; initial setup cost!

Let’s see different tiles examples and its design.

Glazed/ Digital Floor Vitrified Tiles:

The vitrified tiles get a glazed surface, and are called as the glazed vitrified tiles, and in short, this is called GVT. The GVT has one major pro compared with the other types of vitrified tiles, which is the fact that any design or art work can be made on these tiles. The textures like bamboo, stone and wooden are possible only with GV tiles. Digital floor tiles will have a single layer of pigment. It is nearly 1 or 2 mm thick and not suitable for the heavy traffic options. The digital printing technology has brought in additional benefit of incorporating any design. They are best for any requirement, and whatever pattern you imagine can be got with the glazed vitrified tiles. You can also customized tiles design with any pictures or graphics. They are very expensive which can make one hesitant to go for the glazed vitrified tiles.

Explore the video to know about the digital floor tiles production process and how to print design or art on the vitrified tiles.

Here, we are explain about various types of vitrified tiles like nano polished vitrified tiles, double charge tiles, full body vitrified tiles, glazed or digital floor tiles.

Nano Polished Vitrified Tiles:

Double Charge:

The double charge tiles get a thick layer. This is because these types of vitrified tiles are fed by the press to get thick layer of design, and 2 colors. As a result, these tiles are 3 to 4 mm thicker than other tiles. These tiles are perfect for the areas where there is lot of traffic. If you are looking for the tiles to fit into your commercial spaces, then Double Charge vitrified tiles are great. These tiles are apt if you are looking for durable choices, but again, you do not have vast range of patterns, and they are only limited.

Full Body Vitrified Tiles:

If you are looking for colorful options, the full body vitrified tiles are ideal choices. They have colors running all over the body. This full color on the thickness of the tiles has a great advantage. You never get to see the scratches and the cheeping easily, as they can escape the eyes most of the times. These tiles are added with the paint mixture even when they are in the making. One of the great benefits is that the color tends to stay for years, as it runs throughout. While this can be the apt option for the heavy traffic areas, say shopping malls and aero dram, you can see that only a few companies offer these tiles. This is because a special mixture is needed for the new design. Also, the numbers of designs you can see are not much. One more let down can be the most expensive price, but still this is worth what you pay for.

Here we have differentiate these three different types of tiles, vitrified, double charged and digital floor tiles. You can opt any of them as per your requirements. All that you need to know about the tiles you are going to choose for your home or work space.